This collaboration represents a significant milestone in bringing humanoid robots into real-world manufacturing environments, potentially transforming industrial operations. As Boston Dynamics‘ electric Atlas humanoid prepares to enter Hyundai factories in 2025, the partnership signals a new phase in the commercialization of advanced robotics technology.

The Hyundai-Boston Dynamics Partnership Expansion

The relationship between Hyundai Motor Group and Boston Dynamics is entering a new, more intensive phase. After acquiring Boston Dynamics in 2021 for $880 million, Hyundai is now committing to purchase “tens of thousands” of robots in the coming years. This massive order will make Hyundai Boston Dynamics’ largest customer by far, providing both the revenue and real-world testing environments needed to accelerate robot development.

Beyond just buying robots, Hyundai plans to integrate its substantial manufacturing capabilities with Boston Dynamics’ robotics expertise. This combination could address one of the biggest challenges in advanced robotics: scaling production. As Jaehoon Chang, vice chair of Hyundai Motor Group, stated: “Physical AI and humanoid robots will transform our business landscape to the next level. Through our collaboration, we will expedite the process to achieve leadership in the robotics industry.”

The partnership is part of Hyundai’s larger $21 billion investment plan in the United States, which includes $6 billion specifically for innovation and strategic partnerships with American companies. For Boston Dynamics, this relationship provides both capital and a committed customer willing to deploy robots at scale – something that has eluded many robotics companies that develop technologically impressive products but struggle to find widespread commercial adoption.

Atlas Enters the Factory: Humanoids in Real-World Manufacturing

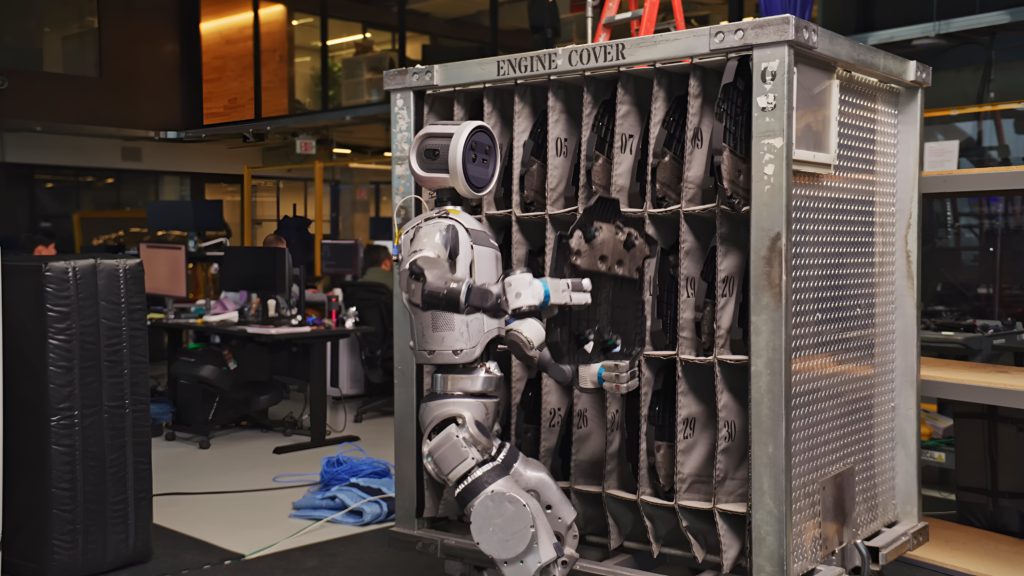

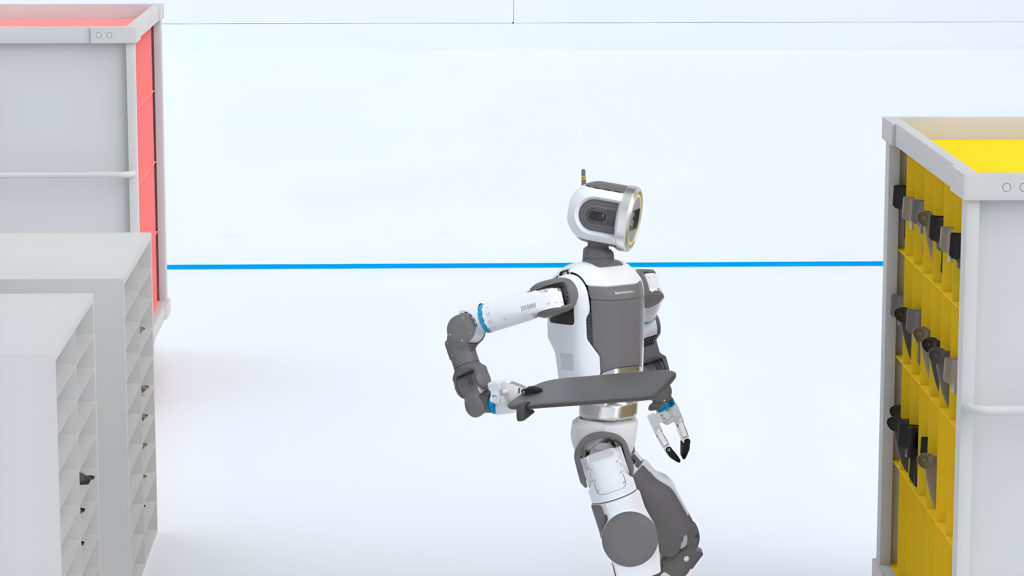

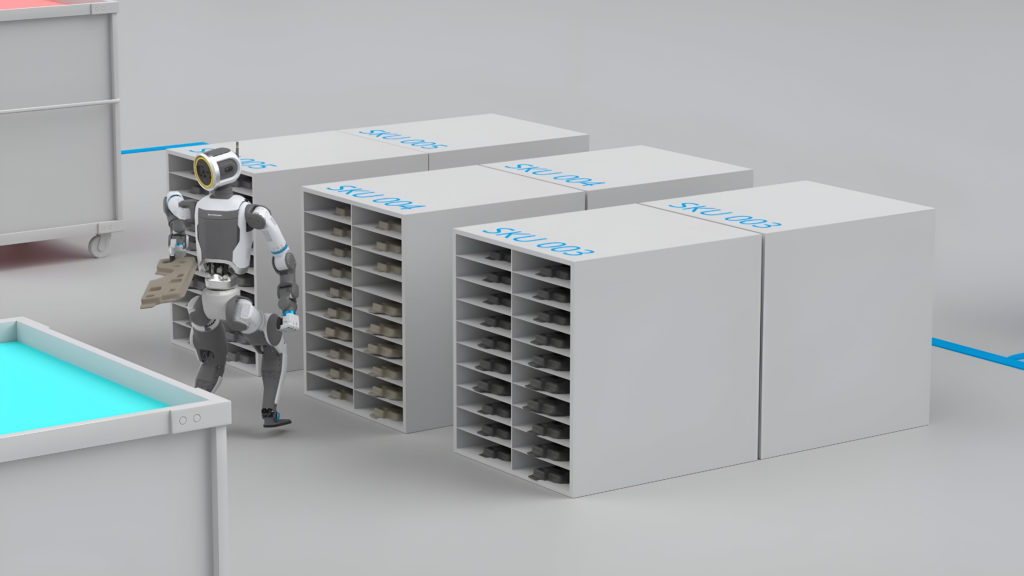

Hyundai is already deploying Boston Dynamics’ Spot quadruped robots for industrial inspection and predictive maintenance across its facilities. The next major step will be introducing the newly redesigned electric Atlas humanoid robot into Hyundai factories. This represents one of the first large-scale deployments of advanced humanoid robots in industrial settings.

Unveiled in April 2024, the electric Atlas represents a complete redesign of Boston Dynamics’ famous humanoid. Unlike previous hydraulic versions known for their dynamic movements, the electric Atlas is specifically designed for practical industrial applications. Boston Dynamics announced it would begin testing Atlas with Hyundai and select partners in 2025, putting it on a timeline to join the small group of humanoid developers with commercial deployments.

When Atlas begins working in Hyundai facilities, it will enter an increasingly competitive field. Companies like Agility Robotics have already deployed their Digit humanoids at companies including Spanx and Schaeffler, while Figure AI is shipping its Figure 02 robots to initial customers. What makes the Atlas deployment particularly significant is the scale – rather than small pilot programs with a handful of robots, Hyundai’s commitment to “tens of thousands” of robots suggests a much more substantial integration into manufacturing operations.

The Broader Humanoid Robot Market Acceleration

The Hyundai-Boston Dynamics partnership represents just one facet of a rapidly accelerating humanoid robot market. According to Goldman Sachs, this market could grow to more than $38 billion by 2035, attracting both established companies and new startups.

The field now includes multiple companies with commercially deployed humanoids. Agility Robotics has placed its Digit robots in facilities operated by GXO and Spanx, while Schaeffler AG has invested in Agility and plans to deploy Digit robots across its global manufacturing network. Figure AI is shipping its Figure 02 humanoid to initial customers and has tested its system with BMW Group for handling sheet-metal parts. Apptronik, while not announcing paying customers yet, has agreements with Mercedes-Benz and GXO Logistics to test its Apollo humanoid.

This increased competition is driving both innovation and standardization in the field. Organizations like ASTM International are working to establish safety standards for humanoid robots in workplaces. Meanwhile, Boston Dynamics has formed partnerships with companies including NVIDIA, Google DeepMind, Toyota Research Institute, and the Robotics & AI Institute to improve its robots’ capabilities. These developments suggest the humanoid robot market is transitioning from research and development to practical commercial applications, with manufacturing environments serving as the initial testing ground.

Industry Convergence: The Robotics Summit & Expo

The momentum behind humanoid robots will be on full display at the upcoming Robotics Summit & Expo in Boston. This event will bring together over 5,000 developers focused on building robots for commercial applications, with humanoids taking center stage in the discussions.

Boston Dynamics’ Chief Technology Officer Aaron Saunders will deliver the opening keynote, “Redesigning Atlas: Boston Dynamics on the Future of Humanoids.” This talk will provide insights into the development of the electric Atlas and explore the challenges and opportunities of building humanoids for real-world applications. It will also offer a behind-the-scenes look at how the Hyundai-Boston Dynamics partnership is advancing robotics technology.

The Summit will also feature a panel on the state of humanoids with experts from Agility Robotics, ASTM International, and Schaeffler. These experts will discuss technical and business challenges, early deployment lessons, safety standards development, and future trends. With over 200 exhibitors and 70 speakers, the event represents a convergence point for the industry at a time when humanoid robots are beginning to move from research labs to factory floors.

This gathering of industry leaders highlights how robotics is becoming increasingly collaborative, with companies sharing insights and best practices to address common challenges. As humanoid robots transition from technological curiosities to practical tools, these kinds of industry events will play a crucial role in establishing standards, sharing knowledge, and accelerating adoption across manufacturing and other sectors. Innovations like The NEO Gamma highlight how these technologies are evolving to meet real-world needs, bringing robotic assistance into everyday environments.