Why do some of Europe’s most prestigious car brands hide a costly secret under their hoods? Behind the gleaming showrooms and impressive performance numbers lies a startling truth about engine reliability. Technical innovations that promised breakthrough efficiency have left thousands of owners facing repair bills higher than their car payments. Major manufacturers like BMW, Volkswagen, and Land Rover rushed to embrace new technologies without fully understanding the long-term consequences.

Modern engineering sometimes brings unexpected lessons in patience and perseverance. From cutting-edge failures to costly design flaws, here are the 17 worst European engines that should have never left the factory floor.

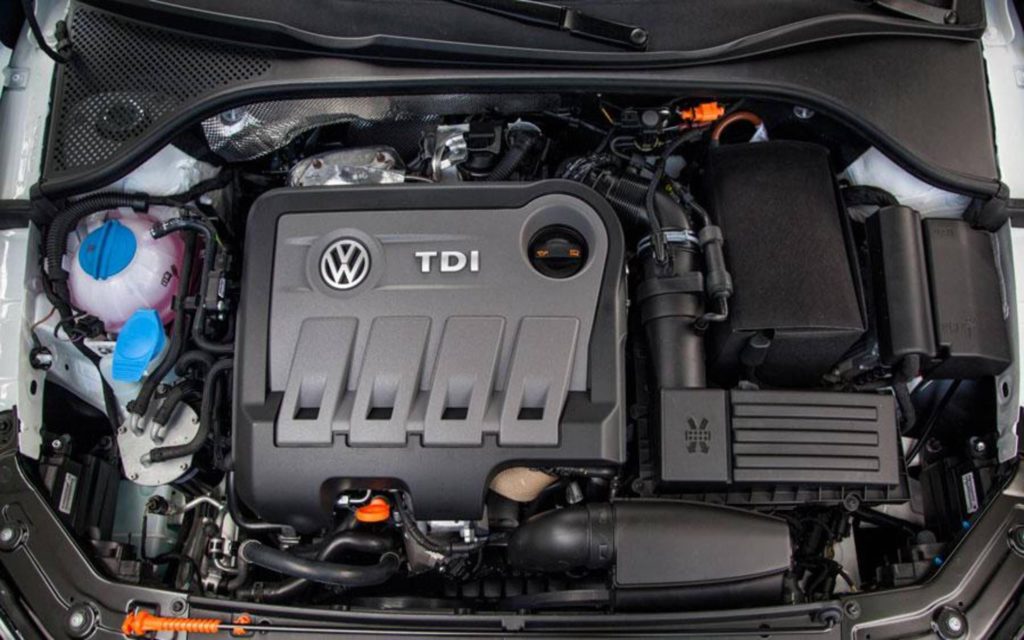

17. Volkswagen Audi 2.5 TDI V6

This ambitious V6 diesel marked Volkswagen’s first serious entry into premium powertrains. From the factory, base models generated a respectable 150 horsepower, while sport variants later achieved 180 horsepower. Despite these promising numbers, a fundamental flaw in the camshaft drive system emerged early in production. Oil consumption typically spiked dramatically after 60,000 miles, requiring frequent top-ups. These catastrophic timing belt failures eventually led Volkswagen to completely redesign their V6 diesel architecture for subsequent generations.

16. Volkswagen Audi 1.8 and 2.0 TFSI (Early Generations)

Direct injection technology promised a quantum leap in efficiency when these engines debuted. Reality proved harsh as 85% of units required major service before reaching 100,000 miles. Carbon accumulation demanded specialized cleaning procedures at 30,000-mile intervals, with each service costing owners $800 in today’s currency. This early experiment with direct injection technology fundamentally changed how manufacturers approached carbon buildup prevention in subsequent engine designs.

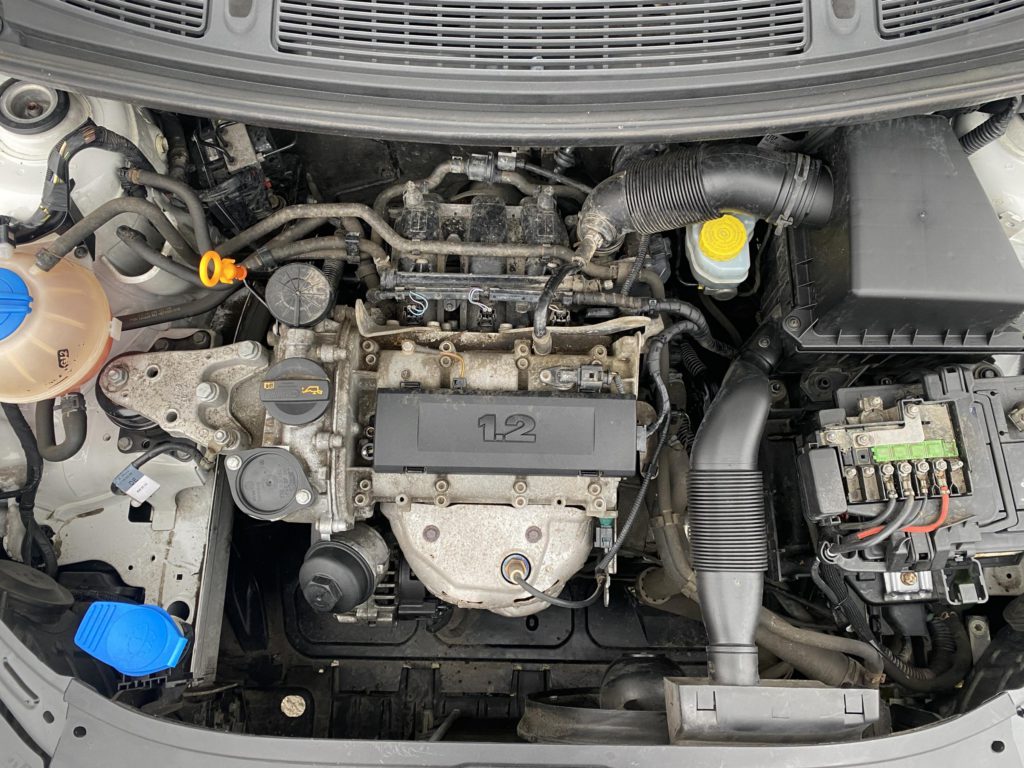

15. Skoda 1.2 HTP

Marketing claimed efficiency, but this three-cylinder engine revealed fundamental flaws almost immediately. Despite manufacturer assurances of 90,000-mile timing belt longevity, catastrophic failures commonly struck at just 30,000 miles. Head gasket failures plagued 40% of engines within their first five years, particularly in warmer climates. The aluminum construction’s thermal sensitivity forced Skoda to abandon this architecture entirely, leading to the development of their more robust EA211 series.

14. BMW N47 2.0d

BMW’s N47 diesel promised class-leading performance but delivered unprecedented reliability issues. One in four engines experienced timing chain failure before reaching 100,000 miles, with problems emerging as early as 45,000 miles. The rear-mounted chain design required engine removal for replacement, driving repair costs to $7,000 in today’s currency. This engineering misstep forced BMW to implement comprehensive timing chain design changes across their entire diesel range. If you’re going by reliability & longevity, then perhaps our list of 14 Harley Davidson engines that last a lifetime might be worth a quick look.

13. Volkswagen 2.0 PD TDI

Pump-düse technology represented Volkswagen’s bold attempt to revolutionize diesel injection. High-pressure operation wreaked havoc on camshaft lobes, affecting 73% of engines before reaching six-figure mileages. Injector failures struck 25% of units by 60,000 miles, necessitating complex repairs. This troubled chapter in diesel development ultimately pushed the industry toward common-rail injection systems.

12. Land Rover 2.7 TDV6

Land Rover’s collaboration with PSA yielded this problematic diesel powerplant. Crankshaft bearing failures struck 32% of engines within four years of service, while oil pump defects plagued early production runs. Complete engine failures typically occurred between 55,000 and 65,000 miles, costing owners upward of $12,000 in current dollars. The widespread failures of this engine led Land Rover to develop their in-house diesel technology for subsequent generations.

11. Saab 2.0 and 2.3 Turbo

Saab’s signature turbocharged engines championed boost pressure but struggled with longevity. Oil sludge accumulated in 42% of engines by 60,000 miles, despite regular maintenance schedules. Turbocharger failures affected 28% of units before reaching 100,000 miles, while oil consumption often exceeded 1 quart per 1,200 miles. These persistent issues eventually contributed to Saab’s declining market position in the premium segment.

10. Renault 2.2 DCI

Renault’s ambitious move into larger diesel engines brought immediate reliability concerns. Failed injectors plagued 38% of engines within their first three years, while electronic control units exhibited widespread failures. Repair costs averaged $4,200 in today’s currency, often exceeding the vehicle’s market value. This problematic engine generation compelled Renault to shift their focus toward smaller-displacement diesel development.

09. Multijet First Generation

Fiat’s common-rail innovation promised efficiency but delivered complications. Oil consumption reached alarming levels of 1 quart per 750 miles in affected units, while injector failures struck 35% of engines within five years. Turbocharger replacements became necessary at an average of 72,000 miles, with costs approaching $3,000. These widespread issues forced Fiat to completely redesign their injection system architecture for the second-generation Multijet.

08. Opel 2.2 16v Ecotec

Engineering shortcuts plagued this engine from its earliest production runs. Timing chain tensioners failed in 45% of units before reaching 60,000 miles, while oil consumption often exceeded 1 quart per 1,000 miles. Heat-related cylinder head warping affected 28% of engines, particularly in Mediterranean markets. The widespread failures of this engine series pushed General Motors to accelerate development of their more reliable Family II architecture.

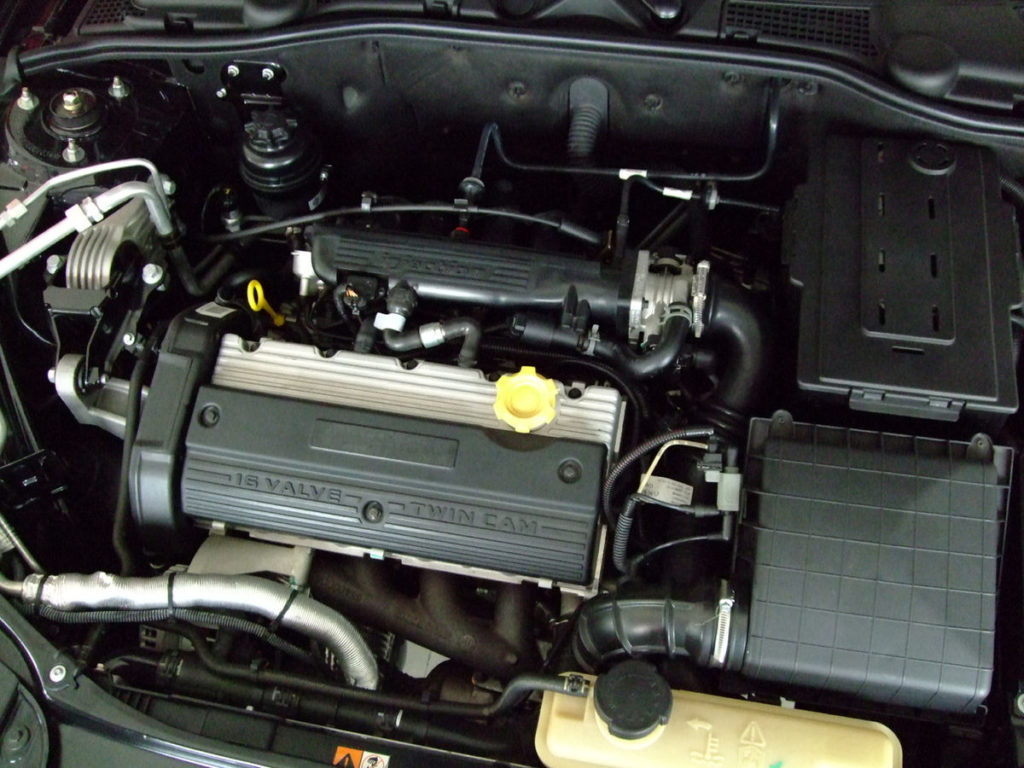

07. Rover K Series

British engineering ambition met thermal reality in this aluminum engine design. Head gasket failures struck 60% of units within six years, while temperature management proved consistently problematic. Manufacturing records revealed cylinder head warping in 33% of engines before reaching 80,000 miles. This engine’s notorious reliability issues contributed significantly to the erosion of consumer confidence in the Rover brand.

06. BMW/PSA 1.6 Prince Engine

Franco-German collaboration yielded impressive power but questionable durability. Early timing chain failures necessitated replacements at 68,000 miles, while carbon buildup affected 47% of engines by 50,000 miles. High-pressure fuel pump failures impacted 31% of units, requiring repairs costing $2,800 in current values. These persistent issues fundamentally altered how both manufacturers approached future joint engine development projects.

05. BMW N63 4.4L Twin Turbo V8

BMW’s innovative “hot-vee” turbocharger placement revolutionized V8 packaging but created unprecedented thermal challenges. Oil consumption reached critical levels of 1 quart per 800 miles in affected units, while valve stem seals deteriorated rapidly under intense heat. Temperature-related failures struck 38% of engines, particularly in high-performance applications, with repair costs exceeding $15,000 in today’s currency. This troubled V8 forced BMW to fundamentally rethink their approach to thermal management in turbocharged engines. Tired of reading about the worst engines? Here’s a list of 15 of the most reliable car engines ever built.

04. Volkswagen 1.2 TSI

Volkswagen’s downsizing strategy stumbled with this compact turbocharged engine. Timing chain failures emerged at an average of 45,000 miles, far below design specifications. Oil consumption peaked at 1 quart per 1,200 miles, while turbocharger failures affected 33% of documented cases. The widespread issues with this engine directly influenced Volkswagen’s return to larger displacement engines in subsequent generations.

03. PSA 1.6 HDI

PSA’s mass-market diesel engine faced persistent durability challenges. Dual-mass flywheel failures struck 42% of units within five years, while turbocharger replacements typically occurred at 65,000 miles. Injection system problems plagued 28% of engines, with repair costs averaging $3,800 in current values. These reliability issues ultimately pushed PSA to accelerate development of their more robust BlueHDi technology.

02. Renault 1.5 DCI

Small displacement met big problems in this widely-deployed diesel. Injector failures affected 45% of units within four years, while turbocharger durability proved consistently problematic. Repair costs averaged $3,200 per major failure, approaching many vehicles’ residual value. This troubled engine generation spurred Renault’s shift toward electrification as an alternative to small diesel development.

01. Volkswagen 1.4 and 1.6 FSI

Early direct injection adoption created unforeseen long-term reliability issues. Carbon buildup necessitated cleaning in 65% of engines by 50,000 miles, while high-pressure fuel pump failures struck 38% of units. Major repairs averaged $4,500 in today’s currency, severely impacting resale values. These widespread problems fundamentally changed how Volkswagen approached direct injection technology, leading to the development of dual-injection systems in later engines.