Great air conditioners are indispensable in our quest for comfort, especially during the sweltering days of summer. At the heart of these cooling behemoths are motors, the unsung heroes, ensuring the seamless operation of our HVAC systems. This article explores the intricate world of air conditioner motor types, unraveling their complexities to provide you with a clear understanding and guidance on making informed decisions, whether you’re a homeowner or an HVAC technician.

Key Takeaways_

- Air conditioners use a variety of motors throughout the unit to cool your home.

- The most common electric AC motor is a permanent split capacitor (PSC) motor due to the high starting torque.

- Your AC unit needs all the electric motors to maintain absolute efficiency while working.

Understanding Air Conditioner Motors

Air conditioner motors are pivotal components in the operation of HVAC systems, driving the circulation of cool air within our spaces.

These electric motors are designed to convert electrical energy into mechanical energy, powering various parts of the air conditioner such as the blower motor, condenser fan motors, and compressor motor.

The efficiency and performance of air conditioners heavily rely on the type of motor employed, with each motor type suited to specific tasks within the unit, from moving air across the evaporator coil to expelling heat from the condenser coil.

Types of Air Conditioner Motors

The HVAC industry has seen a variety of motor types, each with its unique design and operation principles.

Understanding these common types is crucial for anyone involved in the maintenance, repair, or selection of air conditioners.

These motors include split-phase motors, capacitor-start motors, capacitor-start capacitor-run motors, permanent split capacitor (PSC) motors, and electronically commutated motors (ECM), among others.

Split-Phase Motors

Split-phase motors, known for their simplest design, are widely used in air conditioners for tasks requiring moderate starting torque.

These single-phase AC induction motors have separate start and run windings that create the necessary magnetic field to initiate motor operation.

While they offer reliability and a straightforward design, their starting torque is less compared to other types, making them less suitable for high-inertia loads like compressor motors but ideal for fan motors in residential air conditioners.

Capacitor-Start Motors

Capacitor-start motors enhance the starting torque of split-phase motors by incorporating a capacitor in the circuit with the start winding.

This design significantly improves the motor’s starting capabilities, making it suitable for air conditioners requiring a robust initial force to overcome static resistance, such as pump motors and blower motors.

The capacitor shifts the phase of electrical current in the start winding, creating a stronger magnetic field and, thus, a higher starting torque.

Capacitor-Start, Capacitor-Run Motors

Building on the capacitor-start design, these motors include an additional run capacitor, creating a dual-capacitor system that remains active throughout the motor’s operation.

This configuration not only boosts the starting torque but also enhances the motor’s efficiency and power factor, making it a preferred choice for high-performance air conditioners and HVAC blower motors that demand consistent speed and reliability.

Permanent Split Capacitor (PSC) Motors

PSC motors are the workhorses of the HVAC industry, known for their durability and energy efficiency.

Unlike the capacitor-start variants, PSC motors operate with a run capacitor connected permanently to the circuit, providing a smooth and efficient performance with minimal noise.

These motors are commonly found in residential air conditioners and driving fan motors and ensure a comfortable temperature with their reliable operation.

To further enhance indoor air quality, some air conditioners incorporate an AC air exchanger, which helps in exchanging indoor air with fresh outdoor air, reducing pollutants and maintaining a healthy indoor environment.

Electronically Commutated Motors (ECM)

ECM, or brushless DC motors, represent a leap in air conditioner motor technology, offering superior efficiency, variable speed control, and longer lifespan.

These motors use electronic controllers to convert AC power to DC and modulate electrical signals, eliminating the need for brushes and reducing noise and wear.

insider tip

You should contact a qualified HVAC professional if you suspect a faulty compressor motor.

ECMs are increasingly used in modern air conditioners, particularly in variable-speed blower motors, to optimize energy use and improve comfort levels.

When it comes to bedroom or office settings where noise is a concern, the quietest window air conditioner models often utilize ECMs or specially designed PSC motors to minimize sound, ensuring a peaceful environment.

Maintenance Tips for Air Conditioner Motors

Regular maintenance is key to ensuring the longevity and efficiency of air conditioner motors.

Routine checks should include inspecting windings for signs of wear, verifying the operation of capacitors, and ensuring that components like the condenser fans and evaporator coil are free from obstructions.

warning

Never work on an AC motor without disconnecting it from power because you may suffer an electric shock.

Understanding what dry mode in AC is also beneficial, as this function reduces humidity levels, which can indirectly reduce the load on the motor by improving comfort levels without significantly lowering the temperature.

If your AC unit is buzzing every few minutes, it could indicate an issue with the motor or electrical components, necessitating a professional inspection to prevent further damage.

Timely identification and resolution of issues can prevent costly repairs and extend the life of your air conditioning unit.

DIY vs. Professional Help: When to Call an Expert

While some maintenance tasks can be safely performed by homeowners, such as cleaning the condenser coils and checking the air filters, more complex issues involving the motor or electrical components should be addressed by professionals.

Recognizing when to seek expert service can prevent further damage and ensure the safe and efficient operation of your air conditioner.

Innovations and Future Trends in Air Conditioner Motors

The air conditioning industry continues to evolve, with innovations aimed at improving efficiency and reducing environmental impact.

Future trends include the development of smarter, more energy-efficient motors and the integration of advanced technologies that allow for precise control over air conditioning systems.

Staying informed about these advancements can help you make sustainable choices for your cooling needs.

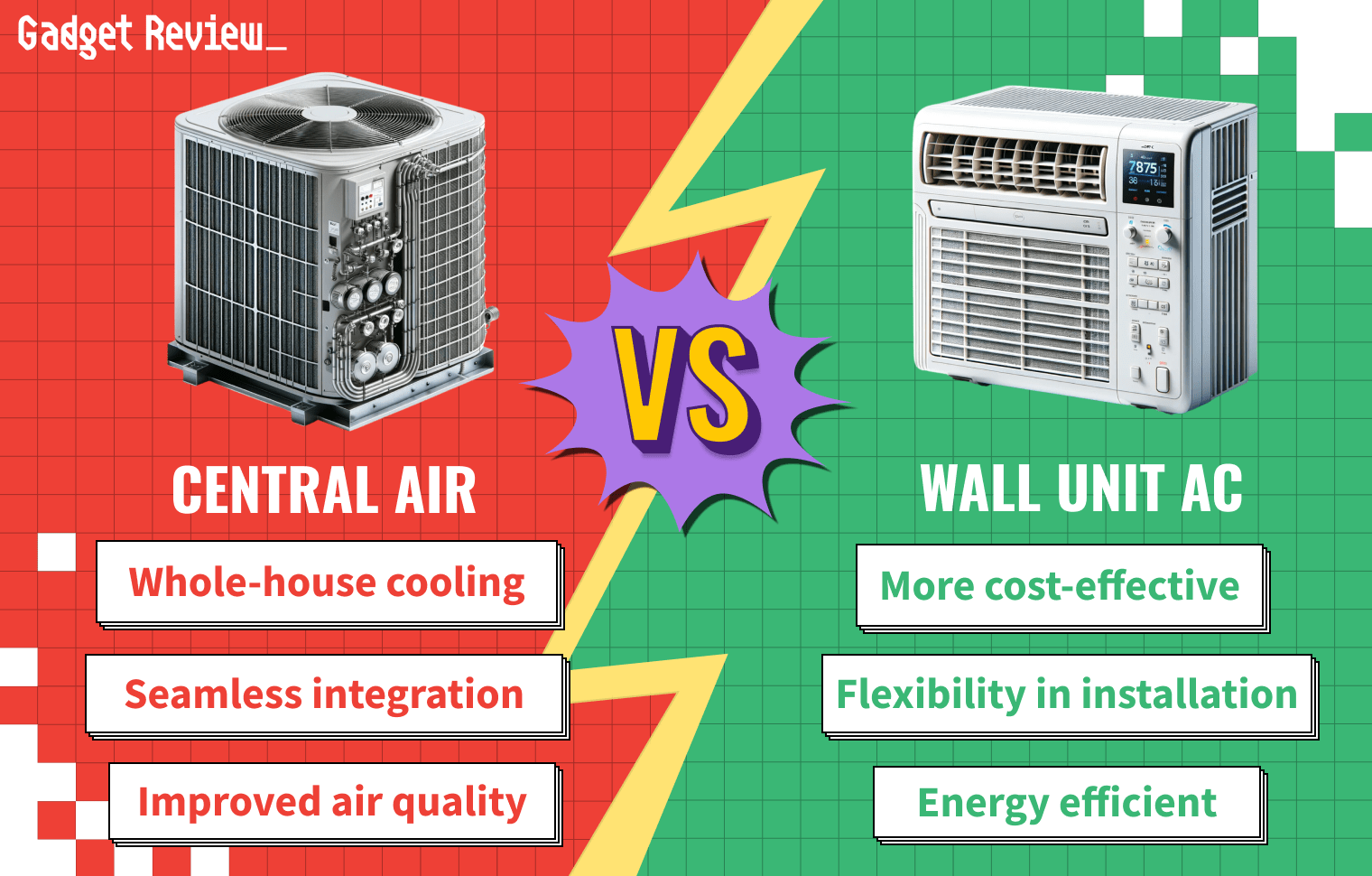

STAT: According to a 2020 US EIA (Energy Information Administration) survey, 22% of Americans have air conditioning but do not use a central AC system. (source)

Understanding the various types of motors used in air conditioners is essential for anyone looking to maintain, repair, or choose an HVAC system.

From the simple yet effective split-phase motor to the highly efficient electronically commutated motors, each type of motor plays a crucial role in the operation of air conditioners.

By familiarizing yourself with these motor types and their applications, you can ensure the optimal performance of your air conditioning unit, contributing to a comfortable and energy-efficient environment.