Classic cars hold a special place in automotive history while revealing the hits and misses of engineering innovation. These mechanical time capsules transformed from daily frustrations into fascinating talking points at car shows. The quirks that once drove owners to distraction now add character and conversation value. Ready to discover which hidden gremlins might be lurking in that vintage beauty you’ve been eyeing?

15. Oldsmobile Diesels

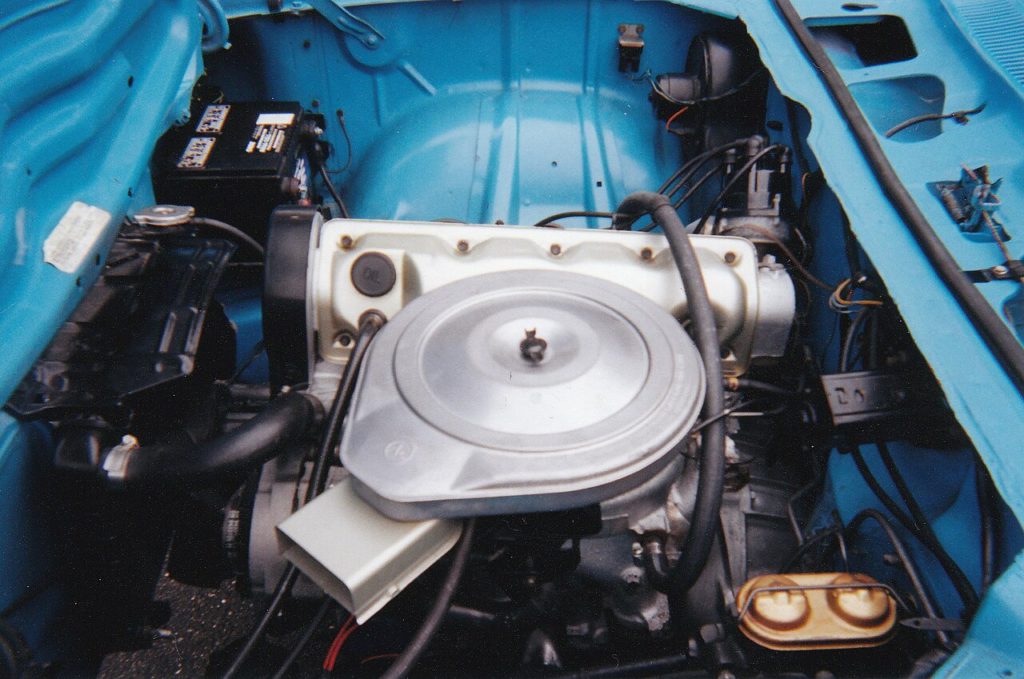

Oldsmobile introduced diesel engines from 1978 through 1985, offering 350 cubic inch V8 and 4.3L V6 variants across numerous GM brands. These powerplants represented a rapid response to fuel economy pressures following the energy crisis. Engineers converted existing gasoline engine blocks to diesel operation without incorporating essential diesel-specific design elements, creating fundamental weaknesses that led to catastrophic failures. The engines lacked proper head bolt clamping force and water separators in the fuel filtration system.

These engines achieved impressive 25-26 MPG economy figures but produced merely 120 horsepower despite their substantial displacement. Starting required extended cranking periods, particularly in cold weather where waits up to two minutes were common. Widespread reliability problems damaged Oldsmobile’s reputation and hindered diesel acceptance in the American passenger car market for decades. Most surviving examples have undergone conversion to gasoline power, while the rare original specimens primarily serve educational purposes as cautionary examples of hurried engineering compromises.

14. Chevrolet Motor Mounts (Mid-1960s)

Mid-1960s Chevrolets contained a serious safety hazard hiding beneath their hoods: rubber motor mounts prone to complete failure. When these components broke, engines shifted position dramatically within the bay, potentially jamming throttle linkages and causing dangerous unintended acceleration. This defect affected numerous popular models including the Impala, Camaro, and Chevy II lineup.

Chevrolet addressed the problem by adding steel safety straps to motor mounts, preventing catastrophic engine movement even if the rubber failed. Modern restorers universally replace these motor mounts with improved designs during renovation projects. This critical safety upgrade prevents both expensive mechanical damage and dangerous driving situations while maintaining period-correct appearance. The modification represents essential preventive maintenance that protects both the vehicle’s mechanical integrity and its occupants’ safety.

13. Chevrolet Vega Aluminum Engine

Chevrolet introduced the Vega’s innovative aluminum engine block in 1971, representing an ambitious attempt to reduce weight and improve efficiency. Engineers designed this powerplant without traditional cylinder liners, instead using a special silicon-aluminum alloy intended to provide durability despite the significant weight reduction. Unfortunately, design flaws quickly emerged as the engines exhibited excessive oil consumption, cooling system inadequacies, and premature wear that frequently led to complete failure well before 50,000 miles. The Vega engine stands as a compelling example of innovation compromised by inadequate development and testing. It’s far from the only classic car to suffer from dangerous or ill-advised features — many dangerous vintage car features have rightfully vanished as a result.

The manufacturing process contributed to the problems as improperly etched cylinder walls and insufficient cooling capacity caused warping under normal operating temperatures. Owners routinely experienced head gasket failures and oil leaks that required expensive repairs. Contemporary restorers typically replace these problematic engines with iron-block alternatives that deliver vastly improved reliability. The few historically minded enthusiasts who maintain original powerplants must implement significant modifications including improved cooling systems and cylinder reinforcement to achieve acceptable durability. The Vega engine stands as a compelling example of innovation compromised by inadequate development and testing.

12. Edsel Teletouch Transmission Selector

The 1958 Edsel featured the innovative but deeply flawed Teletouch transmission selector system that positioned push-buttons for gear selection in the steering wheel hub. This electro-mechanical marvel employed servo motors to actuate transmission shifting, creating a futuristic interface that perfectly captured the space-age optimism of the era. Reliability problems emerged immediately as vibration, electrical issues, and mechanical wear caused frequent system failures.

Edsel’s technical service bulletins suggested the decidedly low-tech repair approach of physically tapping stuck servo motors with a hammer to restore functionality. Contemporary restorers face challenging decisions: undertake complete system rebuilding to maintain historical accuracy or convert to more reliable mechanical linkage while preserving appearance. This feature exemplifies how cutting-edge technology implemented before adequate testing can transform from selling point to liability. The Teletouch system remains both a fascinating artifact of automotive innovation and a cautionary tale about prioritizing novelty over reliability.

11. Rim Blow Horn

The rim blow horn represented an innovative approach to driver safety, allowing motorists to activate the horn by pressing anywhere on the steering wheel’s outer ring. GM, Ford, and Chrysler embraced this technology between 1969-1974, marketing it as an enhancement that kept hands firmly on the wheel. Reality quickly deflated this optimism when drivers triggered accidental honks during routine maneuvers and watched the rubber housing deteriorate rapidly under normal use.

Modern collectors face significant challenges finding replacement parts for these systems. Owners fortunate enough to possess a classic with the rim blow feature often invest in professional restoration of the electrical components to preserve this distinctive piece of automotive history. The system stands as a perfect example of well-intentioned innovation that failed to consider real-world usage patterns—a recurring theme in automotive design history.

10. 1981-83 Imperial Fuel Injection Setup

The 1981-83 Chrysler Imperial featured one of America’s earliest digital fuel injection systems, representing a bold technological advance that fell dramatically short in real-world reliability. This electronic fuel management suffered from persistent grounding problems that caused random stalling, often during crucial driving moments. Owners developed the frustrating ritual of completely shutting down the vehicle before restarting to reset the system when it malfunctioned.

Chrysler dealers ultimately instituted a carburetor replacement program under warranty, effectively abandoning the innovative but problematic technology. Modern restorers face challenging decisions between maintaining historical accuracy with the temperamental original system or installing modified fuel delivery that improves reliability. This particular feature represents the fascinating intersection of automotive innovation and practical limitations, highlighting how pioneering technology often requires multiple generations to achieve the reliability consumers demand.

9. 1974 US Federal Government Mandated

The 1974 federal mandate requiring seat belt interlock systems created perhaps the most universally despised automotive safety feature of the era. This technology prevented vehicle starting until the driver fastened their seat belt, employing notoriously unreliable weight sensors that frequently malfunctioned. Public outrage proved so intense that Congress quickly rescinded the requirement, setting a precedent for consumer pushback against overly intrusive safety regulations.

Vehicle manufacturers responded by relocating the override switch underneath the hood, creating the peculiar situation where drivers routinely opened their engine compartment simply to start their cars. Most 1974 model year vehicles have long since had these systems disabled or bypassed by previous owners. Collectors maintaining these systems in working condition preserve an interesting historical footnote that demonstrates the ongoing tension between safety regulations and consumer acceptance of new technologies that alter established driving habits.

8. Ford and Chrysler Power Door Locks

Ford and Chrysler’s early power door locks defied intuitive design with their awkward plunger knobs mounted directly on door panels. Drivers of vehicles like the 1972 Mercury Marquee Brougham stretched awkwardly across the cabin to secure passenger doors, creating a notably cumbersome experience compared to the familiar switches in other models.

Weekend warriors restoring these classics today often upgrade to modern components while preserving period-correct appearances. This practical modification maintains vintage authenticity while eliminating the frustration of operating the original system. The improvement transforms a dated inconvenience into a seamless experience that enhances rather than detracts from classic car ownership.

7. Hidden Wipers

Hidden wipers prioritized aesthetics over functionality, gracing American cars from the late 1960s to mid-1970s with sleek, uninterrupted hood lines. These systems tucked the wipers neatly below the hood edge when not in use, creating a clean profile that designers loved. Winter weather exposed the critical flaw: snow and ice accumulated between the windshield and hood, frequently jamming the mechanism entirely.

Corvettes suffered particularly from complicated lifting systems that failed during crucial moments when visibility mattered most. The intricate linkages broke down with frustrating regularity, creating dangerous driving conditions. Prospective buyers of classics equipped with hidden wipers should thoroughly inspect these mechanisms before purchase or budget accordingly for restoration. The system represents a perfect case study in design priorities: sometimes looking good comes at the expense of actually working well.

6. Cadillac Wiper Control (1974-1979)

Cadillac’s 1974-1979 wiper control featured a miniature joystick awkwardly positioned on the left dashboard panel. This tiny controller lacked definite detents between settings, creating a frustratingly imprecise interface that challenges drivers even under ideal conditions. The design prevented reliable selection of specific speeds, forcing owners to repeatedly adjust the control during variable precipitation.

Owners frequently experienced wipers unexpectedly returning to their parked position during heavy rainfall when visibility became most critical. Modern enthusiasts restoring these luxury sedans discover that thoroughly lubricating the control mechanism significantly improves functionality. This simple maintenance step transforms an infuriating design flaw into a manageable quirk, allowing owners to enjoy these classic Cadillacs without dreading the first drops of rain.

5. Ford Horn Control on Turn Signal Lever

Ford relocated the horn activation button from the traditional steering wheel center to the end of the turn signal lever in several models including the Lincoln Town Car, Mustang, and Escort. This European-inspired design fundamentally contradicted decades of American driver muscle memory. During emergency situations, owners reflexively pressed the center of the steering wheel, finding only frustration where the horn button should have been.

Ford maintained this counterintuitive design despite widespread consumer pushback and negative feedback. Contemporary owners frequently modify their classics to incorporate traditional steering wheel horn buttons while preserving the original appearance. This practical safety upgrade acknowledges that some design experiments, however bold, simply don’t succeed in real-world conditions where split-second reactions matter. The modification represents the perfect balance between historical preservation and practical drivability.

4. Annoying Key Buzzers

Key-in-ignition warning systems evolved from mechanical buzzers to electronic alerts during the 1970s, increasing dramatically in volume and persistence. Models like the 1969 AMC Ambassador, 1982 Pontiac Firebird, and 1977 Impala featured particularly aggressive warning sounds that activated immediately when the key remained in the ignition with the door open. These well-intentioned safety features quickly became irritants that disrupted concentration during basic tasks like checking under the hood.

Contemporary enthusiasts typically modify these systems during restoration projects, installing more subdued alert mechanisms that preserve the safety function without the jarring auditory experience. This practical upgrade maintains period correctness while acknowledging that some original features detract from rather than enhance the classic car experience. The modification represents the thoughtful balance restorers strike between historical accuracy and modern usability.

3. 1971 GM Deck Lid Louvers

GM introduced deck lid louvers in 1971 as part of their innovative flow-through ventilation system, creating a distinctive styling element that quickly revealed serious functional flaws. These perforated trunk panels permitted water, snow, and road debris to enter the storage compartment freely, creating moisture problems that ranged from damaged luggage to completely frozen trunk lids during winter months. Additionally, concerns arose about potential exhaust fume backdraft entering the passenger compartment.

The system’s continuous blower fan operation drained vehicle batteries even when ventilation wasn’t needed. GM engineers recognized these critical shortcomings and discontinued the feature after just one model year, making these vehicles distinctive rarities in the collector market. Today’s restorers typically modify these systems to improve functionality while maintaining the unique appearance, addressing the practical limitations without sacrificing the visual characteristics that make these cars historically significant.

2. Mono Leaf Rear Springs (60s El Dorado and Toronado)

The 1966 Oldsmobile Toronado and 1967 Cadillac Eldorado pioneered front-wheel drive in American luxury cars but compromised significantly on rear suspension design. Engineers selected a mono leaf rear suspension system—a single, wide leaf spring supporting the entire rear axle—paired with four shock absorbers. This simplistic approach produced a noticeably harsh ride quality that contradicted the luxury positioning of these otherwise revolutionary vehicles.

Knowledgeable collectors now routinely upgrade these suspensions during restoration, installing components that maintain stock appearance while delivering significantly improved comfort. This modification acknowledges the otherwise groundbreaking engineering of these models while correcting their most apparent shortcoming. The approach preserves historical significance while eliminating the ride characteristics that originally disappointed buyers who expected true luxury performance from these premium-priced automobiles.

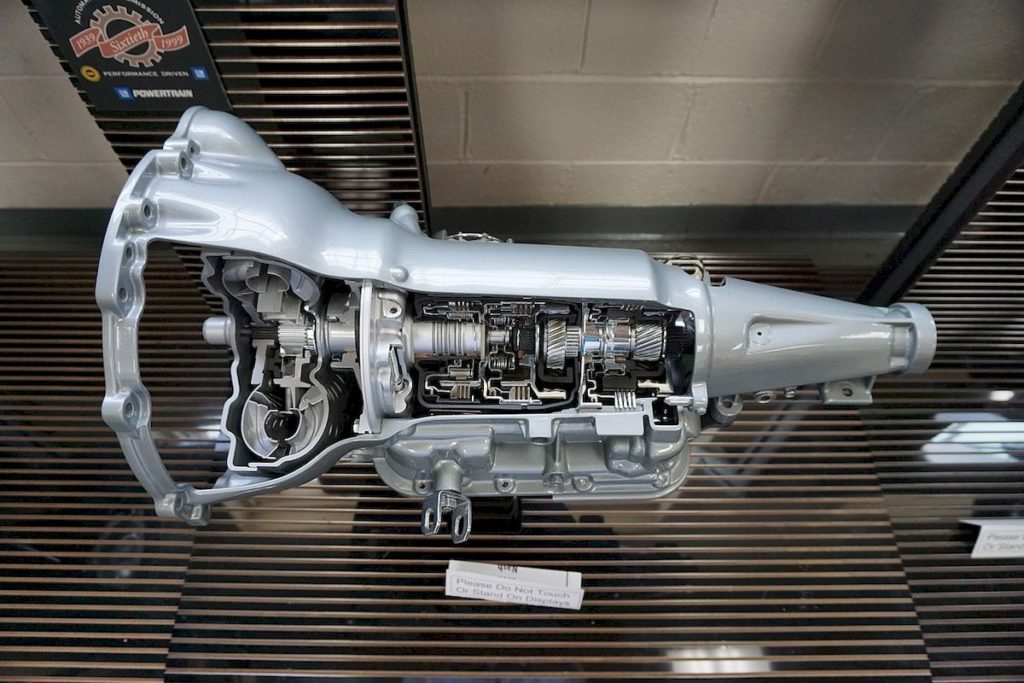

1. Turbo Hydramatic 200 Transmission (GM)

General Motors introduced the Turbo Hydramatic 200 transmission in 1976 as a lightweight, fuel-efficient alternative to the proven TH350. This three-speed automatic featured a unique “metric” pan design and reduced weight to improve fuel economy during a period of rising gas prices. Unfortunately, these advantages came with significant reliability compromises, particularly when the transmission was paired with V8 engines or vehicles used for towing applications.

Statistical evidence suggests few of these transmissions survived beyond 80,000 miles without major repairs, contrasting sharply with the TH350’s typical 200,000-mile lifespan. Knowledgeable collectors routinely upgrade to either the improved TH200-4R or traditional TH350 during restoration projects. This practical modification dramatically improves durability while maintaining period-correct appearance, preventing the frustration and expense of premature transmission failure that originally plagued vehicles equipped with the problematic TH200.