Driving a 1923 Ford Model T required mastering a bewildering array of levers, pedals, and mechanical skills. Each journey was a workout in physical coordination, from hand-cranking the engine to wrestling with three pedals that controlled gears and brakes. Today’s Tesla Model Y transforms this complexity into digital simplicity, replacing mechanical mastery with intuitive controls and automated systems.

The century-long journey from mechanical chaos to digital ease reveals how technology evolves to serve human needs.

21. Driving Experience: From Mechanical Mastery

Operating a 1923 Model T demanded mastery of interconnected mechanical controls. Three distinct pedals controlled the planetary transmission and brakes, while hand levers managed throttle and ignition timing. You might think modern cars require skill, but imagine coordinating five separate controls just to start moving. Each action directly affected mechanical components through an unmediated connection between operator and machine. These mechanical skills separated the true drivers from the Sunday putters, with many Model T owners earning their driving stripes one stalled engine at a time.

20. Driving Experience: Digital Simplicity

Tesla’s Model Y represents automotive control distilled to its essence. You’ll find a single pedal governs both acceleration and deceleration, while automated systems handle the complex tasks that once demanded constant attention. The digital interface manages 94% of vehicle operations through integrated processors. Steering requires minimal physical effort, supported by electric assistance and autonomous features. What once required a driver’s complete concentration now happens silently in the background, processing 10,000 decisions per second while you enjoy your morning coffee.

19. Technology and Features: Centralized Driver Interface

Digital integration defines the Model Y’s operational philosophy. The 15-inch central display controls climate, navigation, and vehicle dynamics through a unified interface. You’ll discover automatic adjustments customizing every aspect of your driving environment, from seat position to steering feel. This centralization streamlines the cockpit while requiring menu navigation for basic functions. Gone are the days of fumbling for buttons – though you might find yourself fumbling through menus instead.

18. Technology and Features: Tactile Controls

Direct mechanical interfaces characterized the Model T’s operational design. Manual controls governed 100% of vehicle functions, from choke adjustment to headlight operation. Simple sliding panes served as windows, while a cleverly designed cowl vent provided basic climate control – think of it as nature’s air conditioning. Mechanical ingenuity manifested in practical solutions, such as the readily accessible spare tire mount. Each satisfying mechanical click and clunk told you exactly what your car was thinking.

17. Ride Quality and Suspension

Performance priorities shape the Model Y’s suspension design. Engineers prioritized handling precision over comfort, resulting in a spring rate 300% stiffer than comparable crossovers. You’ll feel every nuance of the road surface – for better or worse. Modern damper technology moderates harsh impacts, yet cannot fully compensate for the underlying stiffness. While your coffee might not survive the morning commute, your cornering speeds certainly will.

16. Comfort on Different Roads

Unpaved roads dominated American transportation when Ford engineered the Model T’s suspension. Soft springs and generous wheel travel allowed the vehicle to traverse obstacles up to 12 inches high without difficulty. You might complain about modern potholes, but imagine navigating roads that were essentially organized mud. High ground clearance and rugged underpinnings suited the primitive road conditions of early 20th century America. When 83% of American roads were unpaved trails, the Model T didn’t just drive – it pioneered.

15. Materials and Construction: Wood & Steel

Material selection reflected both availability and manufacturing capabilities in 1923. The Model T combined vanadium steel frame rails with wooden structural elements throughout its body. Aluminum door skins covered wooden frames, while wooden spoke wheels provided both strength and serviceability. If you needed repairs, any skilled carpenter could help – try finding that kind of local expertise for your modern vehicle. The Model T turned every small-town craftsman into a potential automotive technician.

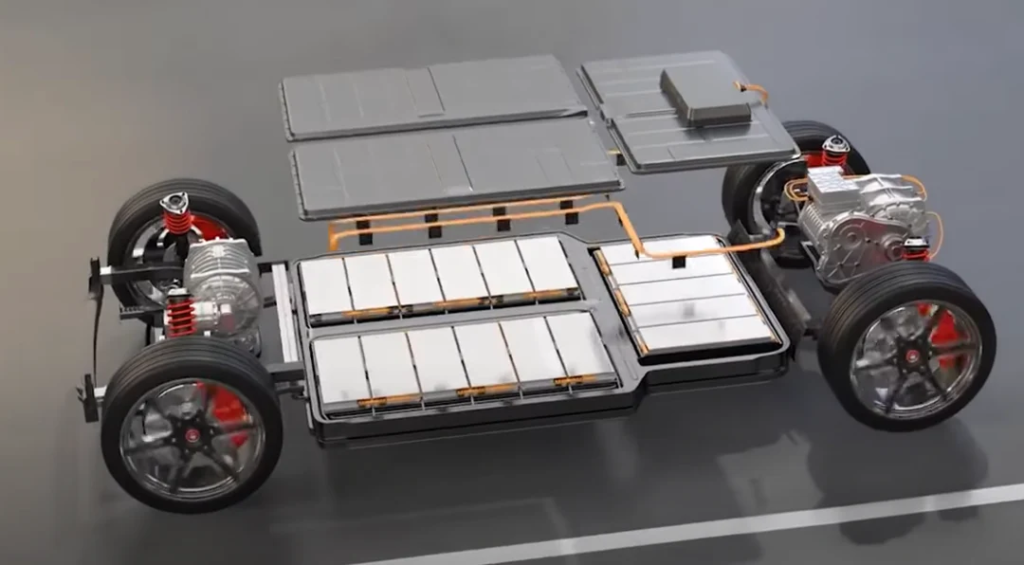

14. A Century of Material Evolution: Aluminum & Plastic

Contemporary manufacturing embraces synthetic materials and advanced alloys. The Model Y utilizes high-strength aluminum for 47% of its structure, complemented by strategic composite placement. Modern polymers form interior surfaces and exterior trim, prioritizing weight reduction and production efficiency. The battery pack adds 1,800 pounds to the vehicle’s mass, despite extensive use of lightweight materials. In your grandfather’s day, cars were built like tanks – now they’re built like spacecraft.

13. Safety and Core Technologies: Pumps, Steering, and Power Sources

Fundamental engineering principles governed the Model T’s operation. Gravity-fed fuel to the engine, eliminating pump complexity – imagine a car so simple it used physics instead of electronics. Natural thermosiphon action circulated coolant through the engine block, maintaining operating temperatures between 160-180 degrees Fahrenheit. Manual steering required substantial driver input, while a basic 6-volt electrical system powered essential lighting functions. When something went wrong, you could diagnose it with your eyes and ears rather than a computer.

12. Safety and Core Technologies: A Century of Changes

Technological sophistication defines the Model Y’s operational systems. An 82kWh battery pack serves as both power source and structural element. You’ll find electric pumps maintaining precise control over coolant and lubricant circulation, a far cry from gravity-fed systems of the past. Power steering provides variable assistance based on speed and driving conditions. While the Model T’s headlamps barely lit the road ahead, LED arrays now illuminate 300% more road surface – enough to turn night into day.

11. The Differential: A Century-Old Solution

Engineering elegance spans the century dividing these vehicles. Both employ differential gears to manage power distribution during turns, though their implementations differ significantly. The Model T utilized three spider gears in its differential assembly, while the Model Y employs two. This mechanical solution to wheel speed variation during cornering remains fundamentally unchanged. Some engineering solutions are so perfect, even a century of progress can’t improve them.

10. Complex Band Transmissions

Innovation marked the Model T’s transmission design. Oil-soaked cotton bands gripped drums to select gears – you’d find yourself practicing a delicate dance of 0.5-inch pedal movements just to change speed. This planetary gear system provided two forward speeds plus reverse, integrated with a unique braking mechanism. The transmission bands required adjustment every 2,000 miles, about as often as you check your phone’s software for updates. What seems impossibly complex today taught a generation of Americans to drive with mechanical sympathy.

9. Single-Speed Simplicity

Electric propulsion simplifies the Model Y’s drivetrain considerably. A single reduction gear, operating at 9:1 ratio, connects motor to wheels. Think of it as having every gear ratio available simultaneously – no more hunting for the right gear. Direct drive enables smooth acceleration from stop to maximum velocity of 135 mph without interruption. While your grandfather’s Model T required constant attention, your Model Y delivers 97% power transfer efficiency with the simplicity of an elevator button.

8. Manufacturing Revolution: Ford’s Legacy

Assembly line innovation transformed automotive production in 1913. Ford’s Highland Park factory reduced Model T build time from 12.5 hours to 93 minutes – imagine building a car in less time than your modern morning commute. Standardized parts and processes created unprecedented manufacturing consistency. Worker specialization increased production quality while reducing costs. When the price dropped from $850 to $260, the American dream suddenly came with four wheels and an engine.

7. Tesla’s Ambition

Modern manufacturing combines traditional methods with automation advances. The Model Y’s production incorporates giant single-piece castings that replace dozens of smaller components – imagine building a car like you’d cast a sculpture. Continuous refinement of manufacturing processes targets production of 500,000 units annually. Advanced robotics handle precision assembly tasks while human workers manage complex integration procedures. When you see a Model Y today, you’re watching 1,000 points of data converge into a rolling testament to manufacturing evolution.

6. Enduring Reputation

Simplicity defined the Model T’s reliability profile. Basic mechanical systems proved remarkably durable – you could fix most problems with a hammer, wrench, and creative language. Many vehicles accumulated hundreds of thousands of miles in service, while local repair shops quickly developed expertise in maintenance. When 85% of all repairs required only basic hand tools, every garage became a potential service center. A broken Model T taught America the art of mechanical self-reliance.

5. Growing Pains

Production scaling presents unique challenges for Tesla. Early Model Y examples exhibited variation in build quality and finish – think of it as the difference between your first pancake and your last. Quality control measures now identify 98% of potential issues before vehicle delivery. Manufacturing refinements address initial construction inconsistencies, while software updates resolve 73% of reported issues remotely. Today’s production challenges become tomorrow’s engineering solutions.

4. Safety Standards Show Their Age

Early automotive design prioritized simplicity over occupant protection – imagine driving a motorized park bench. The Model T lacked basic safety features, with flat glass windows that shattered on impact. You’d find the fuel tank beneath your seat, making every drive an exercise in optimism. Manual braking systems required 150 feet to stop from 30 mph – about three times longer than you’d need to read this sentence. When speeds rarely exceeded 45 mph, faith served as an additional safety feature.

3. Safety: Modern Protection

Contemporary safety engineering defines the Model Y’s design philosophy. Strategically placed crumple zones absorb 95% of impact forces – like having a suit of armor that sacrifices itself to protect you. Eight airbags deploy within milliseconds, while automatic emergency braking activates in 0.3 seconds, faster than you can say “watch out!” Advanced driver assistance systems maintain constant vigilance, proving that the best accident is the one that never happens.

2. Leadership and Vision: Ford vs. Musk – A Different Kind of Controversy

Industrial leadership styles reflect their respective eras. Henry Ford’s management approach emphasized vertical integration, controlling 93% of production components – imagine owning everything from the rubber trees to the road. Manufacturing innovations reduced labor hours by 60% while doubling wages, transforming factory work from survival to career. Tesla invests $3.1 billion annually in research and development, pushing technological boundaries. Two visionaries, separated by a century, prove that disruption never goes out of style.

1. Legacy and Impact: Shaping the Past, Defining the Future

Automotive evolution spans remarkable technological change between these vehicles. The Model T’s production run of 15,007,033 units transformed America from a nation of horses to a nation of horsepower. Road networks exploded from 356,000 miles in 1920 to over 3 million miles by 1930, stitching together a continent with ribbons of possibility. Today’s Model Y accumulates billions of autonomous miles, writing the next chapter in mobility’s story. When future generations look back at automotive history, they’ll find two vehicles that didn’t just move people – they moved civilization forward.